AD7&AD8 Cable Waterproof Standard

The Importance of Waterproofing in Photovoltaic Systems Exposed to Harsh Environments

Photovoltaic (PV) systems are designed to efficiently harness solar energy, often operating in some of the most challenging environmental conditions. From heavy rain and snow to high humidity and flood risks, PV systems must endure exposure to elements that can impact their performance. Waterproofing plays a crucial role in protecting these systems, especially the cables that connect solar panels to inverters and other components. Without proper waterproofing, moisture can infiltrate the cables, leading to detrimental effects. For PV systems in flood-prone areas, those exposed to heavy rainfall, or regions with high groundwater levels, waterproofing becomes even more critical. Ensuring cables meet adequate waterproof standards (e.g., AD7 or AD8) is key to maintaining the reliability and safety of solar installations throughout their expected lifespan.

In addition to basic UV resistance, high insulation resistance, low smoke and halogen-free performance, SUNKEAN has launched AD7/AD8 waterproof cable connection solutions for high humidity and heavy rainfall areas. SUNKEAN not only uses AD7 as the standard performance of conventional cable product lines, but also strives to show the excellent performance of AD8 waterproof cables for more sophisticated projects.

What Are AD7 and AD8 Waterproof Standards?

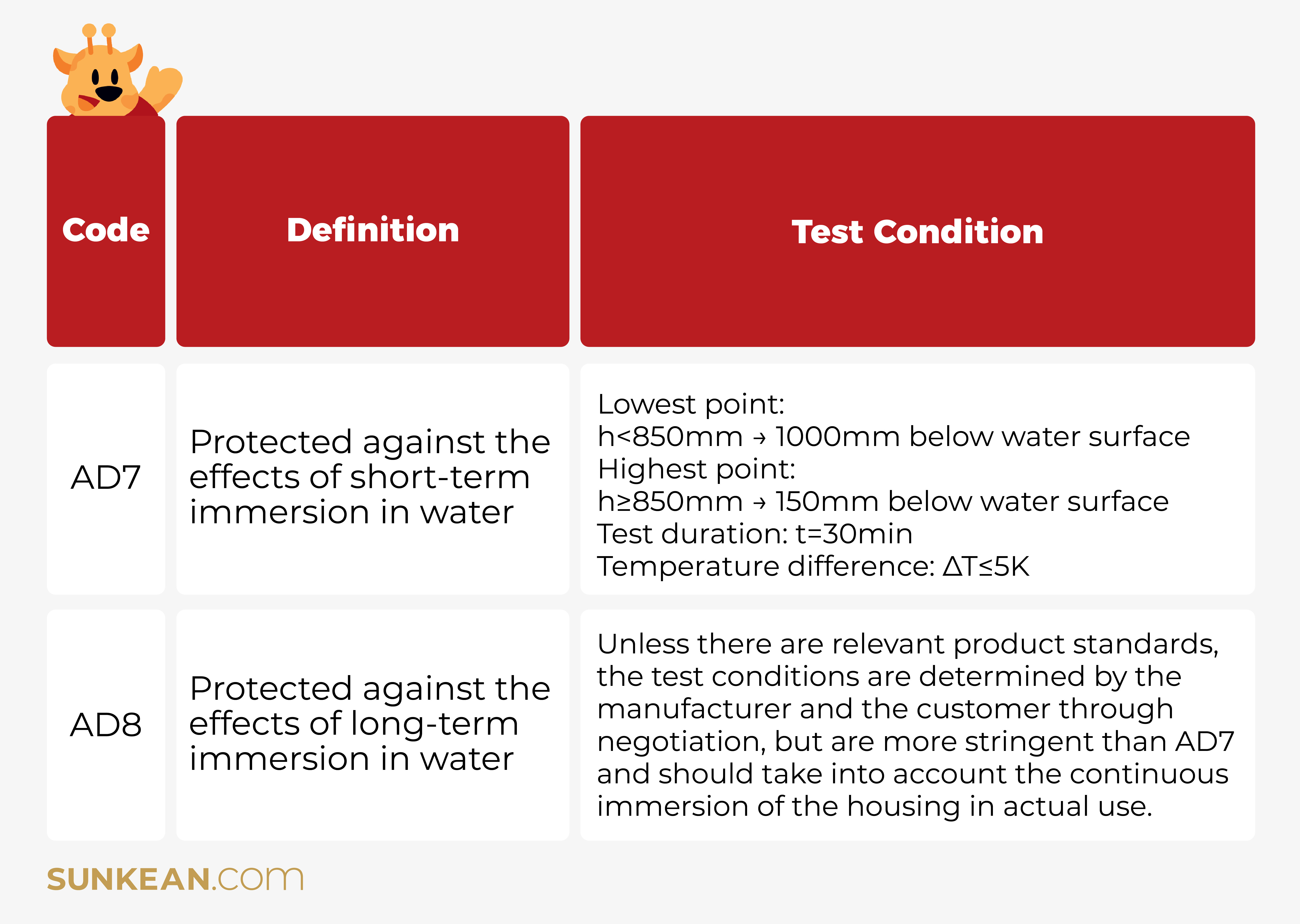

AD7 and AD8 are the most recognized waterproofing grades for photovoltaic cables, defining the extent to which water intrusion is prevented under harsh conditions. These grades are part of a standardized system for classifying the waterproof capabilities of cables and components in electrical systems. Originating from international standards such as IEC (International Electrotechnical Commission) guidelines, these grades provide a framework for assessing the durability and safety of electrical equipment under various environmental conditions.

The establishment of these standards ensures consistency in waterproof assessments and cross-industry communication. Manufacturers must rigorously test their cables to meet the requirements of these grades, including simulating immersion scenarios and pressure tests. By adhering to AD7 and AD8 standards, PV systems can operate reliably in challenging environments, protecting cables from water-related damage and ensuring long-term energy production. These grades enable engineers and installers to confidently select the right cables for a wide range of applications, whether on rooftops, open fields, or submerged in water.

The Key Differences Between AD7 (Submersion) and AD8 (Pressure Submersion)

Conductor: 1×1.5~400mm²

Insulation Color: Optional color

Jacket Color: Optional color

Conductor: 2×1.5~35mm²

Insulation Color: Optional color

Jacket Color: Optional color

Conductor: 1.5~400mm²

Insulation Color: Optional color

Jacket Color: Optional color

Conductor: 2.5~240mm²

Insulation Color: Black

Jacket Color: Black

Why Waterproofing is Critical for PV Systems?

Photovoltaic cables face various environmental challenges, such as rain, flooding, and condensation, that can jeopardize their performance. Below are some typical environmental factors affecting PV cables:

Heavy Rain and Water Runoff PV systems installed in regions with frequent rainfall are at risk of water infiltration. Extended exposure to rain can lead to water accumulating around the cables, increasing the risk of moisture entering the insulation or connectors. Without adequate waterproofing, this could result in electrical shorts and long-term damage.

Flooding and Submersion In flood-prone regions, cables can often be submerged for extended periods. Floodwaters can penetrate cables with poor insulation, causing corrosion of conductive materials and damage to the insulation. This not only affects cable efficiency but also poses safety risks.

Condensation and Humidity Even in environments where cables are not directly exposed to water, condensation may form due to temperature fluctuations or high humidity. This moisture can accumulate within cable joints or sheaths, leading to gradual degradation of the insulation and creating a pathway for electrical faults.

Snow and Ice Melting In colder climates, snow and ice accumulated on solar panels eventually melt, creating runoff. This runoff can collect around connectors and cables, especially in ground-mounted systems, increasing the risk of water infiltration.

Groundwater and Soil Moisture For PV systems with underground cables, exposure to high groundwater levels or persistent soil moisture presents a continuous challenge. Over time, water can infiltrate inadequately waterproofed cables, leading to insulation failure and reduced cable lifespan.

Extreme Weather Events Storms, hurricanes, or typhoons can cause sudden and severe water exposure, such as prolonged flooding or strong water jets. Cables lacking robust waterproofing can fail under such extreme conditions, compromising the entire PV system.

Consequences of Insufficient Waterproofing (e.g., Cable Degradation, Short Circuits, System Failures)

Cable Degradation Moisture entering the cables can corrode the metal conductors, reducing their ability to effectively transmit power. It also degrades the performance of the insulation material, leading to cracks or weakening of protective properties. This makes cables more susceptible to environmental stress and further exposure to water. Prolonged exposure to humid conditions accelerates wear and tear, shortening the overall lifespan of the cable and increasing the need for frequent replacements.

Electrical Short Circuits When water infiltrates poorly insulated cables, it creates unintended current paths, leading to short circuits. Short circuits disrupt energy flow, causing system downtime and reduced energy output. In extreme cases, short circuits can damage other components, such as inverters or junction boxes, leading to costly repairs.

Safety Hazards Water is conductive, so any damaged cables can pose an electrocution risk to maintenance workers and nearby personnel. Continuous water infiltration can cause overheating or electrical arcing, which could ignite surrounding materials and start a fire.

Practical Applications of AD7 and AD8 in PV Systems

Residential Rooftop Solar Systems AD7-rated cables are ideal for most residential rooftop PV systems. These systems are exposed to typical weather conditions, including rainfall, melting snow, and occasional splashes, but rarely experience prolonged or heavy submersion.

Large-Scale Solar Farms Both AD7 and AD8-rated cables are suitable for large solar farms, depending on the specific environmental conditions of the installation site. For solar farms located in areas with moderate rainfall and well-draining soil, AD7 cables are sufficient to handle typical rain exposure and occasional flooding. These installations often incorporate protective design measures, such as elevated cables and conduits, to prevent prolonged submersion. However, in areas with high groundwater levels, frequent flooding, or risk of submersion during extreme weather events, AD8-rated cables are essential to ensure reliable performance, even under prolonged water exposure or pressure.

Floating Solar Projects in Flood-Prone Areas For floating solar installations in flood-prone regions, AD8-rated cables are a must. Floating solar farms, typically installed on bodies of water such as lakes or reservoirs, require cables that can withstand extended submersion under pressure. Similarly, solar installations in flood-prone areas must handle prolonged water immersion. AD8 cables ensure that floating and flood-prone systems can operate safely and efficiently, even in extreme conditions, while minimizing the risk of water-related damage.

In addition to AD waterproof cables, SUNKEAN also provides TÜV 2PfG 2750 and TÜV 2PfG 2962 floating cables, specially designed for floating power stations such as near-shore floating surface power stations. They can meet the high requirements of various floating application scenarios and are perfectly compatible with mainstream connectors. We are willing to answer related questions for you: sales@sunkean.com