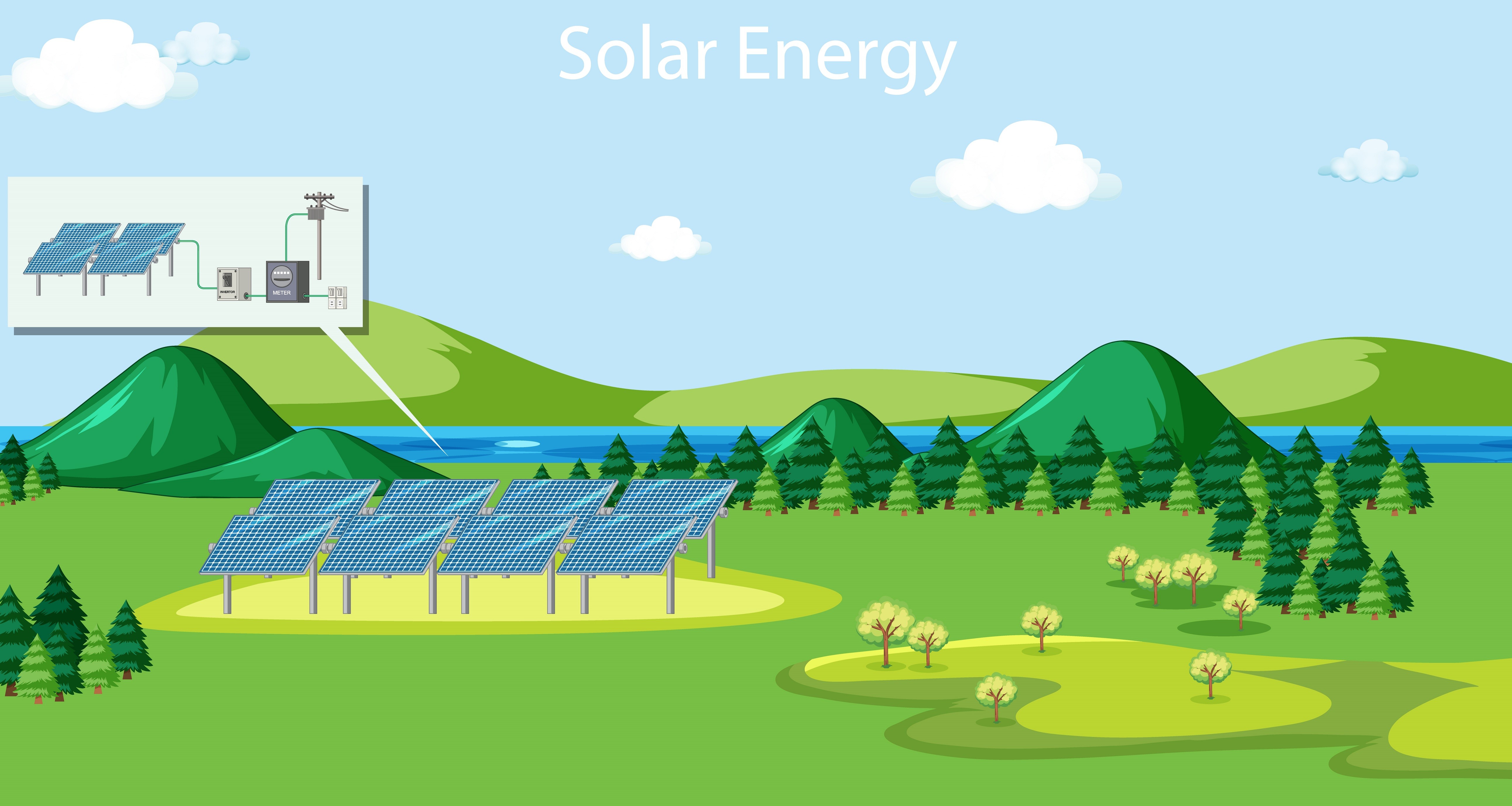

Solar panels are rarely used alone in a solar installation. Instead, they are grouped together to form solar panel arrays. These arrays consist of multiple panels connected in series or parallel to meet specific power generation needs.

In a series connection, the positive terminal of one panel is connected to the negative terminal of the next panel. This increases the voltage output of the array while maintaining the same current. DC cables are used to connect the panels together, ensuring that the voltage is safely transferred through the system. In a parallel configuration, the positive terminals of all panels are connected together, as are the negative terminals. This increases the total current while maintaining the same voltage. The DC cables in this setup need to handle higher currents, ensuring that energy is efficiently transferred without overheating the cables.

The DC cables used for series and parallel connections must be of appropriate specifications to support the current and voltage of the system. These cables are often designed with additional insulation and weatherproof jackets to withstand the effects of outdoor elements, ensuring the longevity of the system and the safety of the user.

C. Off-grid Systems: The Role of DC Cables in Off-grid Solar Installations

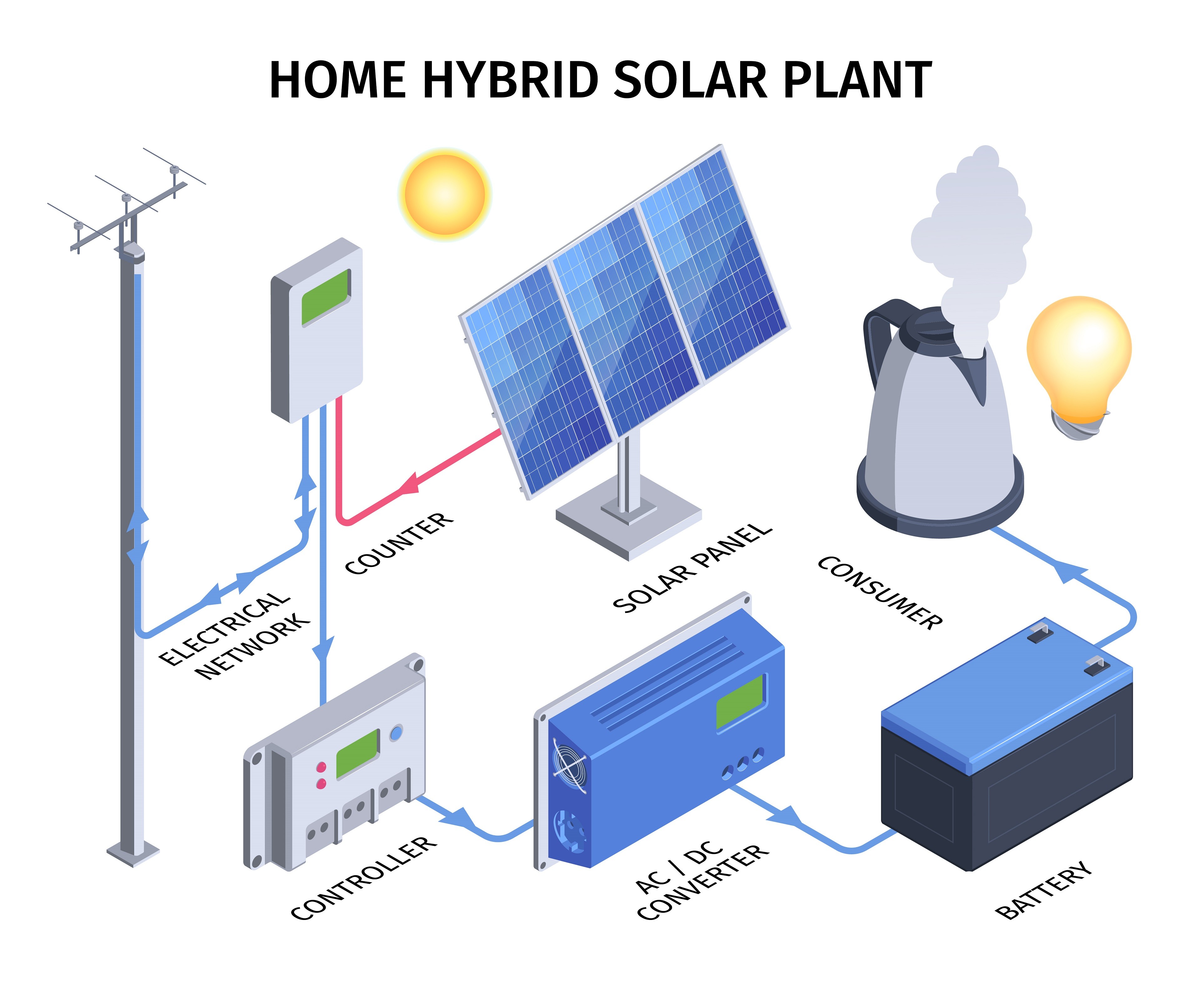

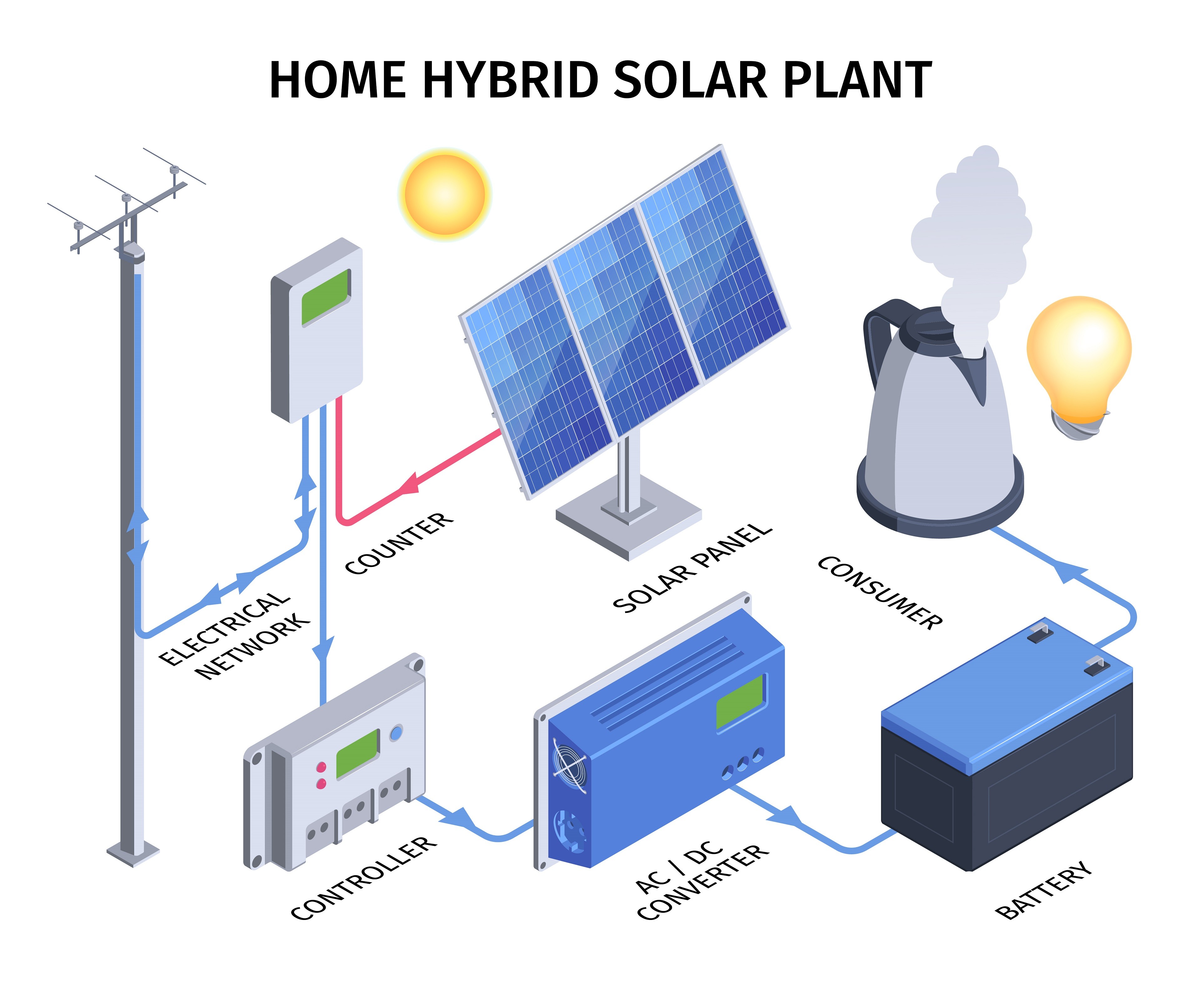

Off-grid solar systems are not connected to the public grid and are becoming increasingly popular in remote areas or among users who want to be independent of traditional power sources. In off-grid systems, DC cables play a vital role in connecting solar panels to battery banks. Solar panels generate direct current electricity, which is stored in batteries for later use. DC cables are used to connect solar panels to a charge controller (if present), and from there to the battery bank. These cables ensure that the energy generated by the panels is efficiently transferred to the batteries without loss or electrical hazards. The stored energy can then be drawn from the batteries to power electrical devices when the sun is not generating electricity (for example, at night or on cloudy days).

Both the battery bank and the charge controller rely heavily on high-quality DC cables that can handle continuous charge and discharge cycles. Since off-grid systems are often used in harsh environments, these cables must be durable, resistant to UV radiation, and able to withstand extreme temperatures.

D. Energy Storage Systems: DC Cables Combined with Battery Storage for Efficient Energy Transfer

As solar energy systems have become increasingly popular, energy storage has become a must-have feature for many installations. Whether in an off-grid system or in a grid-tied setup with backup storage, battery storage allows users to store excess solar energy generated during the day and use it at night or during power outages.

DC cables are key to ensuring that the energy generated by solar panels is efficiently stored in the batteries. These cables connect the solar array to the charge controller, and the controller to the battery bank. When the solar panels generate more energy than is needed, the excess power is sent through the DC cables to charge the batteries. When there is a demand for electricity, the stored DC power is recovered from the batteries and then converted to AC power by the inverter for use in homes or businesses.