Insulation Requirements: Common insulation materials used in AC solar cables include polyvinyl chloride (PVC), cross-linked polyethylene (XLPE), and ethylene propylene rubber (EPR), which offer excellent electrical and mechanical properties while withstanding environmental stressors.

B. Connection to inverters

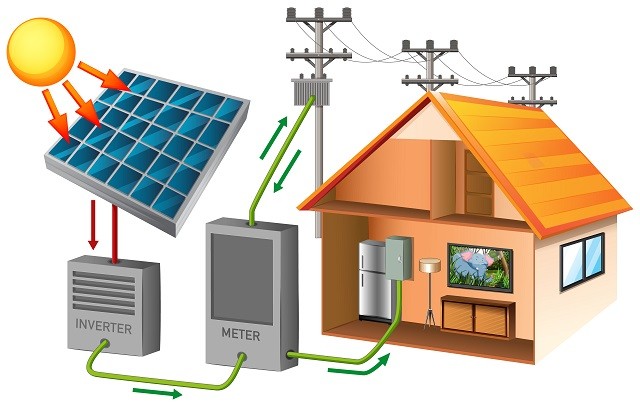

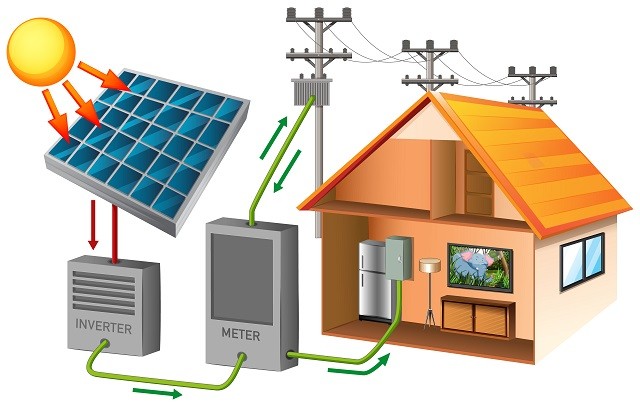

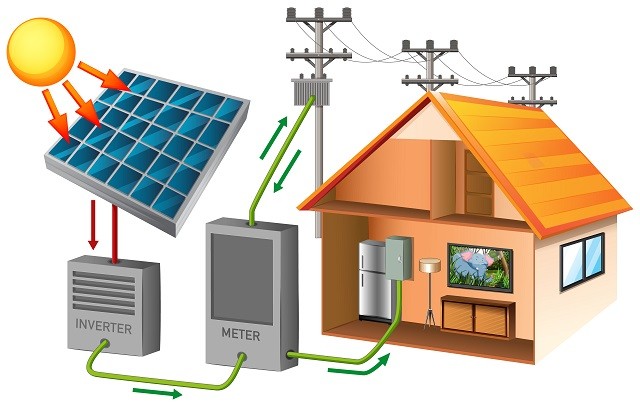

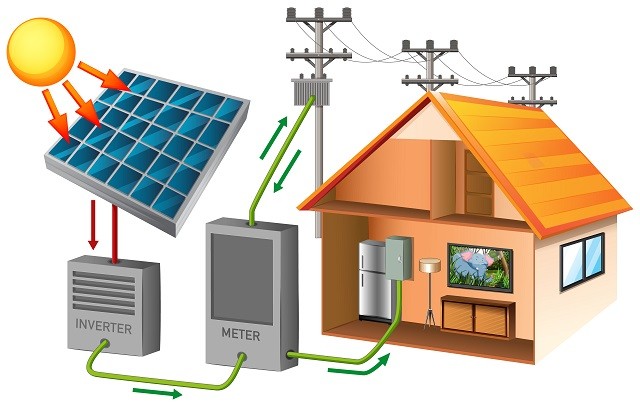

Inverter Input and Output Terminals: The connection between AC solar cables and inverters typically occurs at the input and output terminals of the inverter unit. The input terminals receive AC electricity from the solar panels via the DC to AC conversion process, while the output terminals deliver the converted AC electricity to the electrical loads within the home or facility and, in grid-tied systems, backfeed excess electricity into the utility grid.

Wiring Configuration and Sizing: The wiring configuration may vary depending on the design and layout of the solar energy system, with options for single-phase or three-phase connections to accommodate different load requirements and electrical distribution setups.

Conduit and Protection: Proper grounding and overcurrent protection devices should be installed to ensure the safety and integrity of the electrical system. Ground fault circuit interrupters (GFCIs), surge protectors, and other protective devices help to prevent electrical shocks, fires, and equipment damage in the event of a fault or surge in the electrical system.

C. Compatibility with grid-tie systems

Integration with Utility Grid: One of the defining features of grid-tie systems is their ability to connect directly to the utility grid, allowing surplus electricity generated by solar panels to be exported to the grid for credit or compensation. AC solar cables serve as the conduit through which this excess electricity is transmitted from the solar inverter to the utility grid, enabling bi-directional flow of power and seamless interaction between the solar energy system and the grid.

Voltage and Frequency Compatibility: AC solar cables used in grid-tie systems must be compatible with the voltage and frequency requirements of the utility grid to ensure safe and reliable operation. In most cases, this involves matching the voltage and frequency output of the solar inverter to the specifications of the utility grid, typically 120/240 volts AC at a frequency of 60 Hz in North America or 230 volts AC at a frequency of 50 Hz in Europe and other regions.

Grid Interconnection Standards: Grid-tie systems must comply with specific interconnection standards and regulations established by utility companies, regulatory agencies, and industry organizations to ensure the safety, reliability, and stability of the electrical grid. These standards typically include requirements for equipment certification, system design, protection schemes, and grid synchronization techniques to prevent adverse effects such as voltage fluctuations, frequency instability, and islanding events.

Net Metering and Feed-In Tariffs: AC solar cables play a crucial role in enabling net metering and feed-in tariff schemes by facilitating the bi-directional flow of electricity between the solar energy system and the utility grid. It's essential to ensure that AC solar cables are properly installed, sized, and configured to maximize energy production and optimize the economic benefits of grid-tie solar installations.